Environmental factors can affect the results of highly-sensitive bioprocessing operations. Those factors must be controlled to minimize any possible effects. Among the factors that can be controlled are:

- Temperature

- Humidity

- Air pressure

- Air quality

Maintaining environmental control during the manufacturing or down packing process is part of managing your risk. Avantor® offers products from industry-leading manufacturers backed by a team of specialists with technical and industry experience to recommend the best solutions to meet your needs. Our controlled environment specialists are trained on ISO and IEST protocols. As members of IEST and PDE, they remain current on environmental control manufacturing industry trends and codes.

Turn to Avantor for all your needs concerning environmental control. In addition to products, our specialists offer bioprocessing facility support to help you realize the potential of your discovery or reduce the burden of routine scientific tasks. Our experienced professionals have degrees in biology, chemistry, and engineering and can support upstream and downstream operations.

Environmental factors can affect the results of highly-sensitive bioprocessing operations. Those factors must be controlled to minimize any possible effects. Among the factors that can be controlled are:

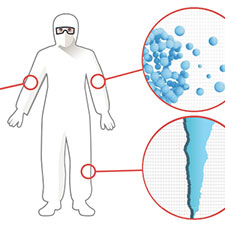

An aseptic condition is one in which no harmful living microorganisms can reproduce or be created. Anything that could contaminate an area is removed using controlled environment solutions when an aseptic environment is necessary.

Cleanrooms and controlled environments are used for ultraclean conditions in research and manufacturing. Get trusted safety products from Avantor.

Our bioprocessing specialists can help improve productivity within your pilot or manufacturing suites by reducing the burden of non-core and routine scientific tasks.

Source all the supplies you need to support early discovery, pre-clinical, scale-up, and commercial vaccine manufacturing.