Masterflex® L/S® MasterSense™ BioPharma Process Drives

Reimage bioprocessing

NEW integrated sensor technology, intuitive touchscreen and MasterflexLive® remote monitoring for the biopharma industry of tomorrow

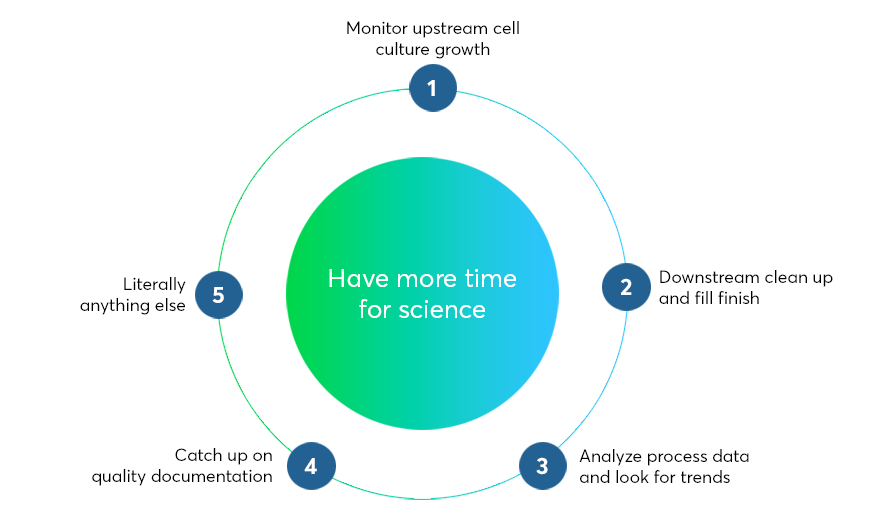

MasterSense™ monitors your media so you don't have to

With the extra time, a process engineer could:

Advanced Connectivity and Control Options

Monitor from anywhere

MasterflexLive

- MasterflexLive is our secure, cloud-enabled platform for real-time remote monitoring of all Masterflex pump parameters

- Monitor critical processes running 24/7 without the need for onsite personnel

- Push notifications alert you to changes in operating conditions and error messages

Flexible Connectivity

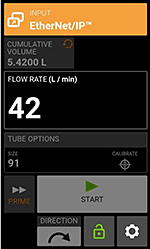

- Your choice of connectivity options—MasterflexLive®, EtherNet/IP, or Profibus

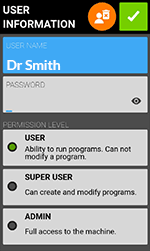

- Three-tier access to pump functionality—use this option to protect your process by controlling who can operate the pump and at what level

- Over-the-air firmware updates—automatically allows you to take full advantage of future enhancements

- Internet connection via Wi-Fi or standard Ethernet (RJ45) jack on rear of drive

Complete your pump system

Choose from 9 pump heads and 20+ tubing formulations to create the perfect pump for your process

Complete Specifications & Product Details | ||||

Types of pump heads accepted | ||||

| 600 RPM (up to 2 pump heads accepted) | 600 RPM Easy-Load Complete System | 600 RPM Easy-Load II Complete System | ||

| Flow Range | 0.006 to 3400 mL/min | 0.08 to 480 mL/min | 0.28 to 1700 mL/min | |

| With EtherNet/IP and MasterflexLive | MFLX07576-10 | MFLX77976-00 | MFLX77976-02 | |

| With Profibus and MasterflexLive | MFLX07576-12 | MFLX77976-10 | MFLX77976-12 | |

Drive Specifications | ||||

| Agency Approvals | UL, cUL, CE | |||

| Warranty | 2 Year | |||

| MasterflexLive | Real-time remote monitoring of all pump parameters. Push notifications alert you to operating conditions and error messages, allowing you to monitor critical pump processes 24/7—no need to be onsite. | |||

| EtherNet/IP or Profibus | Interface directly with either Ethernet/IP or Profibus based process control network(s) (using PLC, SCADA or similar); enables control of all pump parameters via network interface. | |||

| Speed control accuracy (resolution) | ±0.1% (0.1 rpm at 600 rpm) | |||

| Reversible | Yes | |||

| Display | 5” capacitive TFT/RGB touch screen with in-plane switching (wide viewing angle); 800 x 480 pixels | |||

| Digital Dispensing | Yes | |||

| External control - input | 0 to 20 mA, 20 to 0 mA, 4 to 20 mA, 20 to 4 mA; 0 to 10 V, 10 to 0 V, 0 to 5 V, 5 to 0 V; start/stop, direction (CW/CCW), prime via contact closure | |||

| External control - output | 0 to 20 mA, 20 to 0 mA, 4 to 20 mA, 20 to 4 mA; 0 to 10 V, 10 to 0 V, 0 to 5 V, 5 to 0 V; Tach output (open collector), Motor running, Open head, Local/Remote, General alarm | |||

| Motor | Brushless DC with encoder; continuous duty; reversible; 1/10 hp (75 W) | |||

| Open-head sensor | Yes; extension cable included | |||

| Housing materials | 316 Stainless Steel | |||

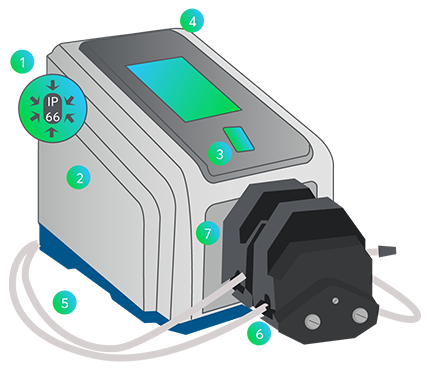

| Enclosure rating | IP66 / NEMA 4X | |||

| Dimensions (L x W x H) | 13" x 9.3" x 11" (33 x 23.6 x 27.9 cm) | |||

| Shipping weight | 28.75 lb (11.794 kg) | |||

| Power | 90 to 260 VAC, 50/60 Hz | |||

Non-contaminating, low shear, and noninvasive makes this pump perfect for Biopharma and healthcare.

Three-tier access and the ability to save and recall programs make your fluidic process secure and accurate.

Our range of tubing formulations ensures the fluid compatibility and the regulatory approvals you need.

Precision manufactured pump tubing gives you accuracy and reliability for critical process applications.

Set up is a breeze

Intuitive touch screen interface, even wearing gloves

- Easy to set up and program

- 5" capacitive TFT/RGB touch screen with a clear, wide viewing angle

- Adjust parameters with a simple touch—even with gloves on

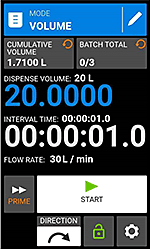

- Operational modes include continuous run, volume dispense, and time dispense

- Batch control and interval/off time in Volume and Time modes

- Antidrip and speed ramping available in Volume mode—ensure accuracy and minimize sample loss

- Easily save and recall up to 50 commonly used protocols, each with a unique name

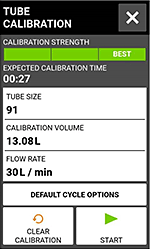

- Know when you hit your mark—graphical indicator lets you know when loaded tubing is optimally calibrated

Take your process to the next level

- Perfect for sanitary environments—316 polished stainless steel housing IP66 NEMA 4X rated for washdown

- Integrated sensors monitor fluid pressure and alert before there is a potential for process failure

- Intuitive digital touchscreen with optimized menu navigation to store and recall standard protocols ensuring continuity-even with wet gloves on!

- Over-the-air firmware updates ensure optimization of your pump system without moving the system while MasterflexLive® cloud storage system securely stores, monitors and generates reports for all Masterflex pump systems

- Powerful performance in a small footprint. Variable flow up to 3400 mL/min (600 rpm). Brushless, maintenance-free motor provides ±0.1% speed control accuracy with 6000:1 turndown ratio

SHOP DRIVE OPTIONS - Qualitative tube calibration ensures tubing is calibrated precisely

SHOP L/S PUMP TUBING - Convenient open-head sensor and antidrip features. Accepts all L/S pump heads.

SHOP L/S PUMP HEADS

Continuous Mode

Time Mode

Volume Mode

Remote Mode

Tube Calibration