Bürkle GmbH – Bring Your Sampling To The Next Level

Tools for sampling of bulk materials. Find sampling solutions for finest powders, granules, or large grains such as corn or nuts.

Samplers for medium viscous substances like oils, emulsions, creams, slurries and semi-solid materials, such as cheese, butter, clay, soap etc.

Sampling equipment for taking samples out of most diverse containers and depths e.g. from small jerrycans up to big basins, tanks or open water courses.

Outstanding surface conditions and most easy to clean, or single-use equipment? We offer most different solutions.

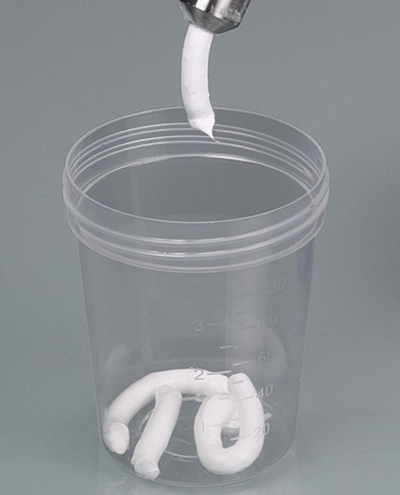

Cleaning of samplers is a demanding, time-intensive task, especially when the material is greasy, strongly adhesive or toxic. Single-use is the solution.

This section includes a variety of small stainless steel tools - from forceps to spatulas - for sampling or processing samples.

Sterilisable stainless steel samplers, that are mostly used in the food industry.

Robust samplers for different kinds of soil samples, e.g. for sampling of meadows, coarse sand or gravel.

The right accessories will help you to round-off your sampling process. This chapter shows a small selection of useful tools to optimise your sampling.

Your expert in sampling helps you to find solutions for the most diverse of applications and highest demands. Optimise your sampling with our sampling solutions.

When taking samples, a random test is taken for overall quantity. These samples serve as the basis for an analysis regarding quality assurance. Only representative and authentic samples can reliably inform about the quality, properties or composition of a particular material.

Very precise material analyses can be carried out with the most 'up to date' technology. However, this technology is no good if an error occurs when the sample is taken, and this error continues throughout all phases of the analysis, with the consequence that the final result of the quality check is wrong. This is the reason why sampling, and the use of appropriate samplers, is that important. Bürkle offers the most comprehensive range of manual samplers. Find out which sampler is ideal for your applications.

Are the single-use samplers suitable for foodstuffs?

What is the expiry date for the sterile items and samplers?

Where do I find the lot number?

Do you provide any certificate for the single-use samplers?

How can I find a suitable sampler?

To find a suitable sampler the following questions need to be answered:

- What medium is being sampled?

- What is the consistency of the medium?

- From which type of container will the sample be taken?

- What volume is required?

- Sampling technique: Target sample, all-layer sample or multi-target sample?

- Disposable or reusable samplers: Does the sampler need to be pure and sterile? Is the material to be sampled greasy, strongly adhesive or toxic? Is simple cleaning without risks to the user possible? We are available if you need any help or consultation.

What about cleaning reusable samplers?

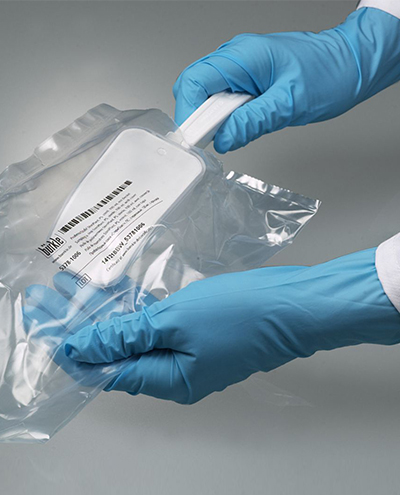

Is there a solution to close the holes adequately to allow sampling directly out of bags?

Why should I use disposable samplers?

The main reasons for using disposable samplers are:

- Highest requirements (purity, sterility, GMP)

- Cost and time intensive cleaning

- Frequent sampling

- High auditing requirements

- Dangerous/aggressive/toxic substances