- Certified ISO (International Organization for Standardization) Class 7 assembly rooms

- Validated equipment and processes that conform to current good manufacturing practices (cGMP)

Quality fluid handling solutions for biopharma

Manage the quality and risk of your fluid handling systems by using Avantor® Masterflex® pumps and single-use technologies in medicine, drug discovery and manufacturing. We adhere to excellence, strict regulatory compliance and transparent reporting in our supply chain operations.

There are two primary considerations for biopharma manufacturers to keep in mind when choosing a supplier of fluid handling products and assemblies: a structured, integrated quality management system (QMS), and supply chain excellence and reliability.

With decades of experience in sterile fluid handling, Avantor® has a proven track record of effectively managing risk and keeping production lines running for our biopharmaceutical customers.

We implement stringent quality processes and procedures when sourcing and delivering fluid management products like single-use components and pumps. Our customers rely on these rigorous standards to reduce contamination risk, improve utilization of resources, and reduce waste and costs.

Avantor can also reduce supply chain risks with our robust, global selection of our own products, like single-use solutions and Masterflex® pumps, as well as products from best-in-class manufacturers available from our channel brand, VWR.

From component qualification and manufacturing operations to in-process testing and final product release — we collaborate to anticipate and solve any challenges, delivering products you can trust.

Reduce your risk and move research forward

Keep your research, scale-up and production moving forward safely and efficiently with Avantor’s quality risk management (QMR) program. This is a proactive approach to assess, control for, review, correct and communicate about any potential risk to the quality of our fluid handling systems.

As part of our overall quality management system, the QMR program is applied systemically — from the risk-based audits that evaluate the capabilities of new suppliers to our internal procedures to assess and mitigate risks in our own processes and facilities. Key elements include:

Redundant cleanroom manufacturing facilities

Certified ISO 9001 quality system

- Compliant with FDA and EU cGMP requirements

- Robust and timely complaint handling and corrective and preventative actions (CAPA) programs

- Risk-based quality management approach

Complete regulatory and product compliance program

- Detailed certificate of compliance accompanies all single-use assemblies

- Backing certifications for assembly components are retained and readily available upon request

- Animal origin-free or EMA/410/01 compliant materials

- Sterility validation per ANSI/AAMI/ISO 11137 (VDmax25)

- Sterile barrier shelf-life validation per ISO 11607

- Supply chain statements

- BPOG standardized extractables testing protocols and results

- Endotoxin (USP85) and particulate (USP788) lot release testing available

Managing risk in your global single-use supply chain

With the rapid growth of single-use quality systems for drug production, choosing the right single-use manufacturer can help mitigate risks associated with ensuring regulatory compliance, manufacturing, and quality requirements of these systems.

Customer-focused supply chain excellence

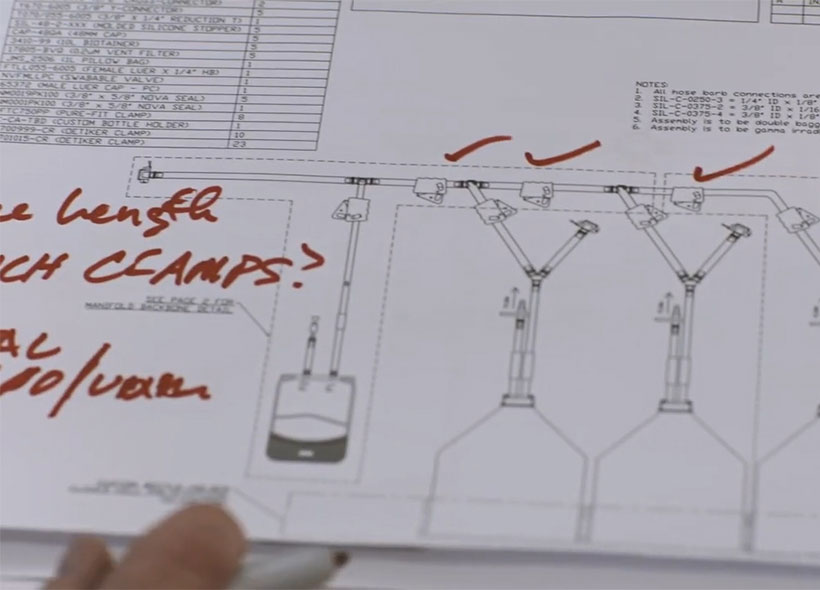

Our quality and security programs are enhanced by customer-centric channel and supply chain operations that support every stage of your biomanufacturing process. Avantor’s skilled technicians understand your unique requirements, and collaborate to design robust, modular solutions that help decrease the complexity around quality, regulatory and security requirements.

In addition, a comprehensive supplier management program vets and qualifies first and second sources of key components to ensure a predictable delivery of products.

Our quality assurance process includes:

Quality and change control

- Through our own internal quality assurance team and change control systems we ensure regulatory compliance.

- We help you stay in control of changing situations and minimize risks associated with changes to the manufacturing process with our efficient change notification program.

- We provide complete, consistent, reliable and transparent change notification, proactively.

Collaborative planning, forecasting and replenishment (CPFR)

- Avantor assures true redundancy through a robust CPFR program — working together early in the process and throughout the design and implementation phase to avoid supply chain disruption. Our critical materials care team directly engages with you to demonstrate, through service level reports, supply verification.

Documentation

- Necessary documents, such as product validation, certificates of conformance, quality and analysis are available either digitally or by request.

Local support

- Avantor’s global team of field-based technical experts help you match your project’s requirements with high quality suppliers of bioprocessing materials.

Supplier auditing and integrity

- Proactive, risk-based audits enable us to understand the capabilities of new suppliers and collaborate effectively to promptly address CAPA if needed.

Optimize fluid handling, and single-use manufacturing, through associate training

How a new training room at Avantor Fluid Handling is ensuring the reliability and quality of your single-use systems.

Best practices in the qualification of fluid handling systems

When we qualify fluid management systems, there are multiple best practices we implement to ensure supplies such as single-use assemblies and components do not affect the quality of research or manufacturing results.

Chemical compatibility tests

Gross leak test

Extractables study

To prevent changes in materials of construction or the manufacturing process, we conduct standardized extractables studies. Our protocol includes a selection of the following:

- Test solvents

- Test articles

- Ratio of surface area to volume

- Pre-sterilization conditions

- Test conditions

- Analytical methods

Quarterly testing

Change management

To help ensure the ongoing qualification of fluid handling systems, we perform science-based assessments whenever there is a change in any of the following:

- Materials of constructions

- Manufacturing processes and sites

- Test methods

These changes are then qualified, and we notify and provide updated qualification documentation to our customers.

Learn more about our fluid-handling solutions

We work hand in hand with customers to design personalized solutions that are flexible, scalable and optimized for YOUR needs. Learn how this innovative approach can help you scale up quickly.

Avantor’s fluid handling design, manufacturing and distribution are available globally to meet the growing demand for biologics.