Liquid Pumps Technical Equations and Information Tables

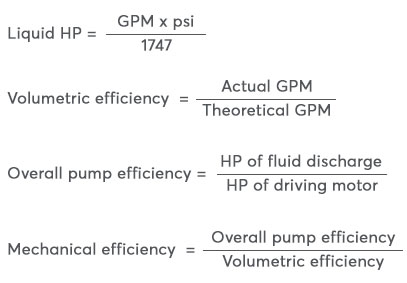

Efficiency Formulas for Rotary Positive Displacement Pumps

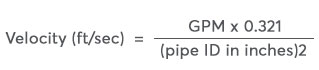

Pipe Velocity

- It is best to allow 10 pipe diameter upstream and 5 pipe diameter downstream leading to the pump suction.

- Try to keep pipe velocities around 10 ft/sec for good practical results.

- Doubling the pipe diameter increases the capacity of the pipe four times.

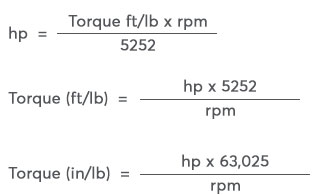

Rules of Thumb for Motors

At 3600 rpm: motor develops 1.5 ft/lb per hp

At 1800 rpm: motor develops 3.0 ft/lb per hp

At 1200 rpm: motor develops 4.5 ft/lb per hp

At 575 volts, a 3-phase motor draws 1.00 amps per hp

At 460 volts, a 3-phase motor draws 1.25 amps per hp

At 230 volts, a 3-phase motor draws 2.50 amps per hp

Approximate rpm at Full Load for Medium Sized Motors

| Poles | rpm 60 Hz | Synch speed | rpm 50 Hz | Synch speed |

|---|---|---|---|---|

| 2 | 3500 | 3600 | 2850 | 3000 |

| 4 | 1750 | 1800 | 1450 | 1500 |

| 6 | 1150 | 1200 | 950 | 1000 |

| 8 | 850 | 900 | 700 | 750 |

Loss of Air Pressure Due to Friction

(Per 100 Feet of Pipe, 100 psi Initial Pressure)

| Free-air capacity in cfm (at 14.7 psi) | Equivalent capacity in cfm (at 100 + 14.7 psi) | 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" |

|---|---|---|---|---|---|---|---|

| 10 | 1.28 | 1.38 | 0.09 | 0.03 | 0.007 | ||

| 20 | 2.56 | 1.42 | 0.34 | 0.10 | 0.026 | 0.012 | |

| 30 | 3.84 | 3.13 | 0.74 | 0.23 | 0.056 | 0.026 | |

| 40 | 5.13 | 5.55 | 1.28 | 0.38 | 0.096 | 0.044 | 0.013 |

| 50 | 6.41 | 8.65 | 2.00 | 0.60 | 0.146 | 0.067 | 0.020 |

| 60 | 2.84 | 0.84 | 0.210 | 0.095 | 0.027 | ||

| 70 | 3.85 | 1.12 | 0.280 | 0.130 | 0.036 | ||

| 80 | 5.01 | 1.44 | 0.360 | 0.160 | 0.046 | ||

| 90 | 6.40 | 1.85 | 0.450 | 0.200 | 0.058 | ||

| 100 | 7.80 | 2.21 | 0.550 | 0.250 | 0.069 | ||

| 125 | 12.40 | 3.41 | 0.850 | 0.380 | 0.107 | ||

| 150 | 18.10 | 4.91 | 1.200 | 0.540 | 0.150 | ||

| 175 | 6.80 | 1.640 | 0.730 | 0.200 | |||

| 200 | 8.79 | 2.120 | 0.950 | 0.260 | |||

| 250 | 3.300 | 1.480 | 0.400 | ||||

| 300 | 4.710 | 2.100 | 0.570 | ||||

| 350 | 6.450 | 2.860 | 0.770 | ||||

| 400 | 8.300 | 3.700 | 0.990 | ||||

| 450 | 4.650 | 1.270 | |||||

| 500 | 5.790 | 1.560 | |||||

| 600 | 8.45 | 2.230 | |||||

| 700 | 3.000 | ||||||

| 800 | 4.000 | ||||||

| 900 | 5.050 | ||||||

| 1000 | 6.200 |

Loss of Air Pressure Due to Pipe Bends

(Per 100 Feet of Straight Pipe)

| Angle of pipe bend | Loss of pressure in psi per pipe ID | |||||

| 1/2" | 3/4" | 1" | 1-1/4" | 1-1/2" | 2" | |

| 45° | 0.73 | 0.92 | 1.18 | 1.55 | 1.85 | 2.35 |

| 90° | 1.60 | 2.00 | 2.50 | 3.40 | 4.00 | 5.10 |

Flow of Air through Orifice

(with Discharge of Orifice at 14.7 psia and 70°F)

| Supply pressure (psig) | Flow of air in cfm per orifice size | |||||||||

| 1/32" | 1/16" | 3/32" | 1/8" | 5/32" | 3/16" | 7/32" | 1/4" | 9/32" | 5/16" | |

| 65 | 1.15 | 4.49 | 10.10 | 17.90 | 27.90 | 40.30 | 55.20 | 71.80 | 89.90 | 111.70 |

| 70 | 1.21 | 4.77 | 10.80 | 19.10 | 29.70 | 42.80 | 58.80 | 76.40 | 95.70 | 118.80 |

| 75 | 1.30 | 5.06 | 11.40 | 20.20 | 31.50 | 45.40 | 62.30 | 81.00 | 105.50 | 126.00 |

| 80 | 1.37 | 5.35 | 12.10 | 21.10 | 33.30 | 48.00 | 65.80 | 85.60 | 107.40 | 133.10 |

| 85 | 1.44 | 5.64 | 12.70 | 22.50 | 35.10 | 50.60 | 69.40 | 90.30 | 113.20 | 140.30 |

| 90 | 1.52 | 5.92 | 13.40 | 23.70 | 36.90 | 53.20 | 72.90 | 94.80 | 119.00 | 147.50 |

| 95 | 1.59 | 6.21 | 14.00 | 24.80 | 38.70 | 55.70 | 76.50 | 99.40 | 124.90 | 154.60 |

| 100 | 1.66 | 6.50 | 14.70 | 26.00 | 40.50 | 58.30 | 80.00 | 104.60 | 130.70 | 161.80 |

| 125 | 2.03 | 7.94 | 17.90 | 31.70 | 49.50 | 71.40 | 97.78 | 127.10 | 159.80 | 197.50 |

| 150 | 2.40 | 9.28 | 21.20 | 37.50 | 58.40 | 84.40 | 115.40 | 150.40 | 189.00 | 233.30 |