Custom fit your mAbs downstream process

You have developed a unique monoclonal antibody therapy and it requires a unique manufacturing process. You need a partner who knows the ins and outs of the downstream process and which holistic solutions will work best for you

Capitalize on Avantor’s technical expertise and consultative approach to improve productivity, maximize resource use and mitigate risk so you can focus on breakthrough innovations. We offer flexible solutions — tailored to your exact needs — that optimize every step of your mAb downstream process. From aseptic, single-use fluid pathways to more efficient buffer management, and effective viral inactivation to quality resins – we help reduce costs and process time and increase downstream yield.

Customize and streamline your mAbs downstream operations

Comprehensive and customized support to reduce viral burden downstream

Our scientists and application specialists understand the complexities of mAbs viral clearance and provide options for removing critical impurities. This consultative approach is supported by innovative products, such as a sustainable alternative, easy-to-use viral inactivation solution, high performance chromatography resins and buffers, and customized, system-agnostic fluid handling technologies. We tailor our approach to meet your needs, and effectively remove the burden of viral and other impurities downstream.

Expert strategies to improve mAb capture productivity

Integrated buffer preparation solutions that optimize your mAbs process

J.T. Baker® Viral Inactivation Solution

Improve viral inactivation efficiency and minimize introduction of impurities.

PROchievA™ recombinant protein A

Enhance your separation power and increase product purity.

Our value section

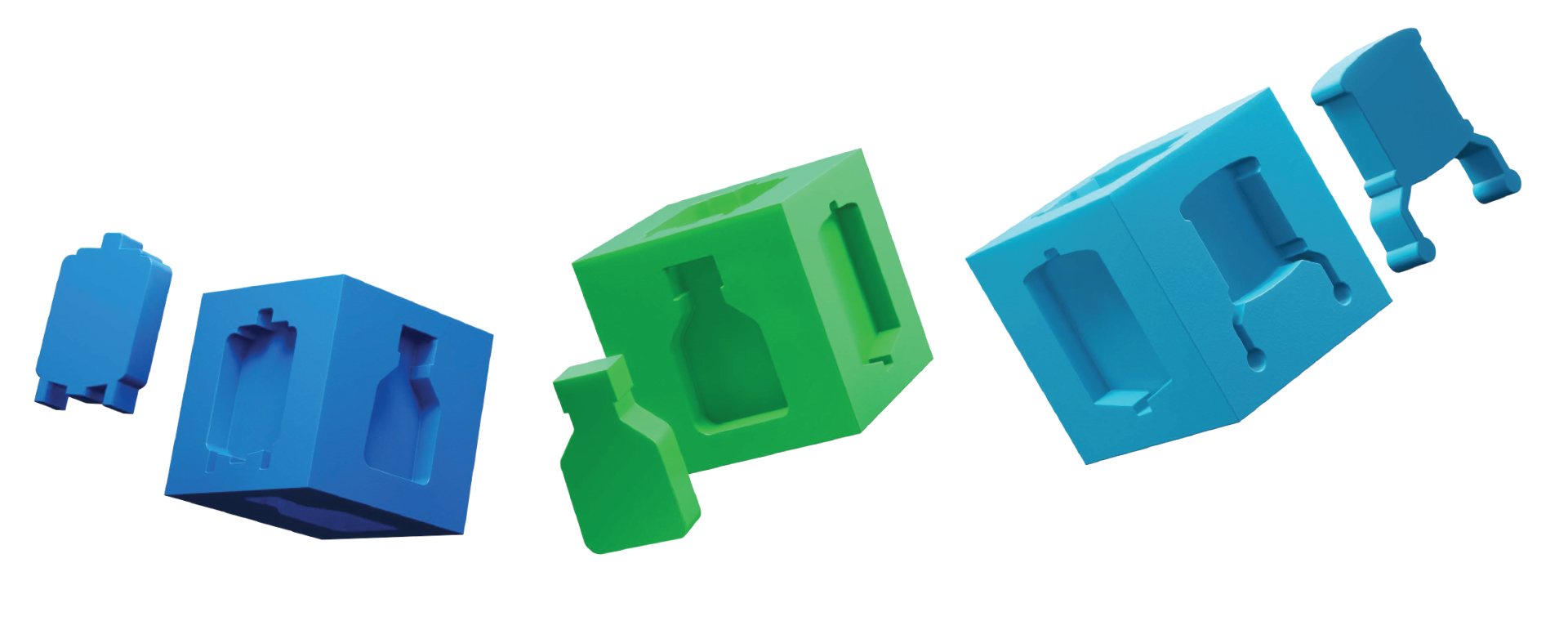

Custom fit your downstream process

We collaborate to design flexible solutions for every step in the process — from buffer management to viral inactivation, chromatography and viral clearance — that can be configured for your unique needs.