Kontrollierte Umgebung, Sicherheit und PSA

In jedem Labor, Reinraum, kontrollierten Umgebung oder jeder Einrichtung hat die Sicherheit von Mitarbeitern und Produkten oberste Priorität. Avantor ® bietet eine umfassende Auswahl an Produkten für kontrollierte Umgebungen, Sicherheit und persönliche Schutzausrüstung (PSA) für eine gesunde und sichere Arbeitsumgebung.

Eine umfassende Palette an Lösungen zum Personen- und Produktschutz von Branchenführern und Marken, denen Sie vertrauen.

Alle Produkte, die Sie für die Behandlung von Unfällen, Verletzungen und die Wundversorgung vor Ort benötigen.

Alles, was Sie brauchen, um Ihre Einrichtung so sicher, sauber und kontaminationsfrei wie möglich zu halten.

Von Druckern über Umweltüberwachungsgeräte bis hin zu Verpackungen: Avantor bietet die Produkte, die für einen effizienten Betrieb Ihrer Anlage sorgen.

Erledigen Sie die Arbeit sicher, indem Sie die richtigen Werkzeuge und Materialien verwenden.

Benötigen Sie kompetente Beratung? Rufen Sie noch heute einen unserer Spezialisten an!

Unsere engagierten Spezialisten verfügen über das nötige Fachwissen, um Sie bei der Einrichtung und Instandhaltung kontrollierter Umgebungen und Reinräume zu unterstützen.

Entdecken Sie Lösungen für Ihre kontrollierte Umgebungen und Arbeitssicherheit von unseren ausgewählten Lieferanten.

Sehen Sie sich die neuen Produkte für kontrollierte Umgebungen und Sicherheit von Avantor und branchenführenden Herstellern an.

Lassen Sie sich von unseren Anbietern bei der Aufrechterhaltung einer sicheren und kontrollierten Umgebung unterstützen.

Sehen Sie sich unsere umweltfreundlicheren Sicherheits- und Reinraumartikel an – entweder nachhaltig produziert und verpackt oder recycelbar.

Arbeitsabläufe in kontrollierten Umgebungen

Was ist eine kontrollierte Umgebung?

Eine kontrollierte Umgebung ist eine Umgebung, in der mehrere Umweltfaktoren mit Hilfe von Geräten für kontrollierte Umgebungen überwacht und kontrolliert werden. Diese Parameter umfassen:

- Partikel

- Luftfeuchtigkeit

- Temperatur

- Druck

- Segregation

Was ist ein Reinraum?

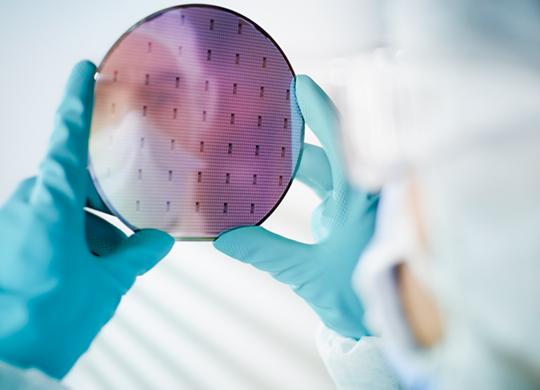

Reinräume sind kontrollierte Umgebungen, in denen die Anzahl der Schadstoffe bzw. Verunreinigungen auf eine bestimmte Partikelgröße pro Kubikfuß oder Kubikmeter begrenzt ist. Reinräume werden regelmäßig geprüft, um die Einhaltung der Standards sicherzustellen. Zudem sind Systeme zur Kontrolle der Umgebung vorhanden, die Staub, chemische Dämpfe, luftgetragene Mikroben und Aerosolpartikel begrenzen.

Reinräume werden von Fertigungsunternehmen eingesetzt, wenn ein hohes Maß an Sterilität erforderlich ist, um negative Auswirkungen auf das hergestellte Produkt zu vermeiden. Reinraumlösungen variieren je nach den Anforderungen des Herstellers und werden in verschiedenen Branchen eingesetzt, darunter:

- Pharmazeutische

- Biotechnologie

- Medizinprodukt

- Biowissenschaften

- Luft- und Raumfahrt

- Halbleiterfertigung

- Optik

- Militär

- Energieministerium

Geräte zur kontrollierten Umgebungsnutzung werden eingesetzt, um die Partikelkontamination zu verringern und sicherzustellen, dass Feuchtigkeit, Temperatur, Luftdruck und andere Umweltfaktoren innerhalb der entsprechenden Parameter bleiben.

Geräte und Zubehör, die notwendig sind, um die erforderlichen Reinraumstandards zu erfüllen.

Laborgeräte und Zubehör für kontrollierte Umgebungen sorgen dafür, dass Reinräume die erforderlichen Standards einhalten. Hierzu zählen u.a.

- HEPA-Filter

- ULPA-Filter

- Luftschleusen

- Luftduschen

- Spezielle Schutzbekleidung

- Lösungen für das Umgebungsmonitoring

Welche Standards gelten für einen Reinraum?

Die Standards für Reinräume basieren auf der Anzahl der Partikel, die in einem Kubikfuß oder einem Kubikmeter Luft gemessen werden. Reinräume werden entweder nach dem Federal Standard 209E der USA oder nach ISO 14644-1 klassifiziert.

Der Federal Standard 209E klassifiziert Reinräume mit Zahlen wie „Klasse 1.000“ oder „Klasse 10.000“. Die Klassifizierung basiert auf der Anzahl der Partikel mit einer Größe von 0,5 μm oder mehr, die in einem Kubikfuß Luft zulässig sind.

Der ISO 14644-1-Standard klassifiziert Reinräume mit kleineren Zahlen wie „3“ und die Klassifizierungen basieren auf einem dezimalen Logarithmus der Anzahl der Partikel 0,1 μm oder größer, die in einem Kubikmeter Luft zulässig sind.

Benötigen Sie Beratung zu Sicherheit oder Produkten für kontrollierte Umgebungen? Wir helfen Ihnen gerne.

Kontaktieren Sie uns, um mit einem Mitglied unseres Teams zu sprechen.